If a broken tap is stuck in a nearly completed workpiece, you'd wish you had EDM (electrical discharge machining) equipment to remove it by erosion. Yet acquiring an EDM machine just for your hobby does not appear to be an option... Oh well, read on:

Instructions for building different types of erosion devices which can be assembled with minimal effort are available on the Internet. Starting out with the idea proposed by Ben Flemming (http://www.lindsaybks.com/bks9/edm/index.html), I built such a device. The electrical circuit is straightforward and the mechanics are also relatively easy to put together.

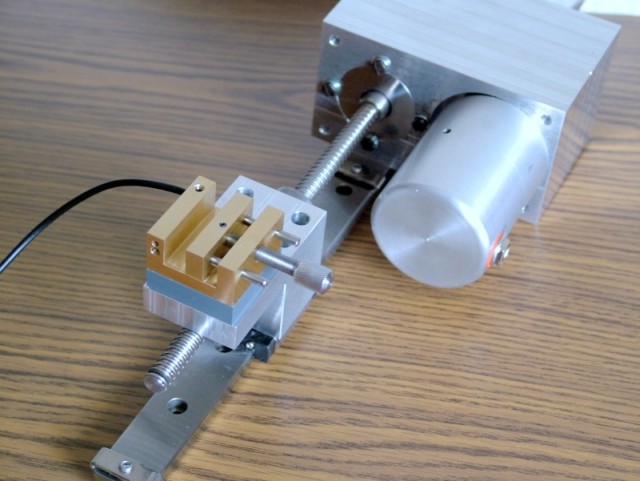

A simple power supply is used to charge a bank of EDM capacitors, the capacitance of which can be selected. An electrical discharge occurs when the electrode touches the workpiece. Exactly at that time, a motor pulls the electrode back and the capacitor is recharged. Under electronic control, the motor will now again advance the electrode towards the workpiece and the process keeps repeating itself.

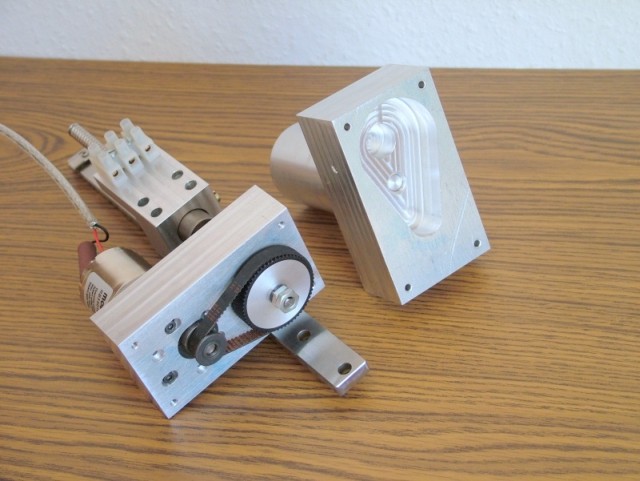

Advanced by a geared motor driving a ballscrew, the electrode is supported by a small linear guide rail. This simple drive mechanism can be attached to a vertical drill or a mill.

The sample workpiece illustrates the EDM results with various elctrodes including graphite, copper, and carbide. Extensive testing showed that tungsten works very well as an electrode and distilled water as EDM fluid.

After I completed the EDM unit, I broke only one tap -- and that could be easily removed by EDM.