In the past, I owned a small Proxxon MF70 CNC mill. This tiny machine is great for milling and engraving small signs. But the machine's Y axis travel is unfortunately limited to 40 mm. I therefore sold it and used my Wabeco mill and the accessory Perske spindle for engraving jobs. Due to the long machining times, the Wabeco mill was often inaccessible for other jobs -- a real shortcoming. That is why I started to think about building a small CNC router large enough to engrave workpieces as large as a standard Eurocard (European standard for PCBs, 100 mm x 160 mm). I was actively assisted by a friend from the main German CNC forum (Peters CNC-Ecke). I could concentrate on milling the required components from CAD drawings on my Wabeco mill.

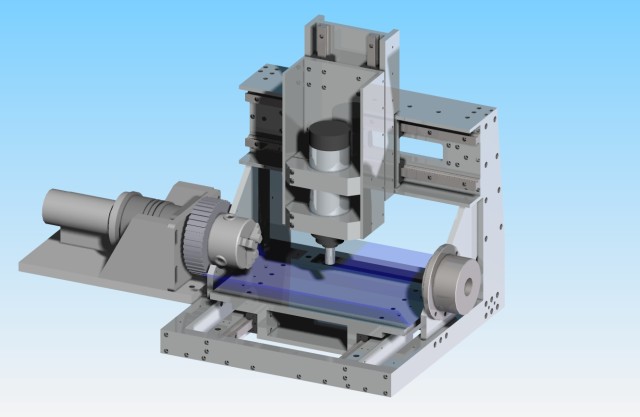

These photographs show that all parts are bolted together, that I constructed the machine with linear way rails and ballscrews, and that I once again used servo motors.

The spindle is a 0.8 kW water cooled China spindle cooled by PC water cooling product, i.e. a passive radiator. Initial tests confirmed that the radiator is adequate for cooling the spindle.

Homing and limit switches, a manual controller for setting up the CNC jobs and the control unit for the variable frequency drive, the former being attached to the router, make the router easy to work with.

First trial run: Isolation milling of a PCB. For protection, spindles and ways are covered. Still, chips keeps flying all over the place -- I will probably have to add an enclosure. I put up some videos on Youtube. A more detailed report on the project can be found in the German CNC forum: http://www.cncecke.de/forum/showthread.php?t=71581

Because I intend to also use the rotary axis for the router, the rotary axis will be the next project to complete.