measurments at model engines

When an engine works, one would like to know more about it:

What’s its idle speed? How many rpm does it reach during defined strain?

Which is the engine output?

In technical literature, several measuring techniques are described.

I would like to introduce the procedures used by myself.

Output measurement / rpm measurement

With

the running engine winding up a thread round a drum, and a weight FG

fixed to the thread,

I only have to measure the time t, which is needed to lift

up the weight to a high h. The Output P can be calculated by the

following equation:

![]()

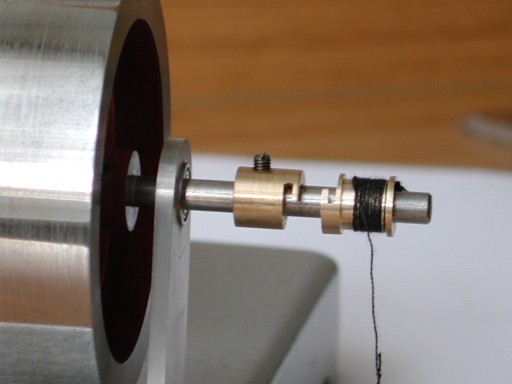

The

measuring arrangement is shown in the picture:

One clutch is fixed to the crankshaft being extended for this purpose, the

other part sliding on the shaft while the engine starts.

After the engine has reached its idle speed, I move the loose part of the clutch

until the claws hook in. From the distance covered by the weight, I fix a lenght

of 1m and measure the time needed (luckily, I used thin yarn because when the

weight reaches the drum you have to stop the engine, otherwise the thread tears

which prevents the weight from turning).

This measuring arrangement afterwards even allows to calculate the number of

revs reached during measuring.

The diameter d of the drum (I used 8mm) determines the

perimeter u (which is the lenght of thread wound round the drum during

one turn). The total way is proportioned to a bigger number of turns. If

the thread is thin enough, the increase of the drum diameter in case of multiple

layer winding can be ignored. Otherwise you will have to use a wider drum.

In consideration of the dimensions the number of revs can be calculated by the

following equation:

![]()